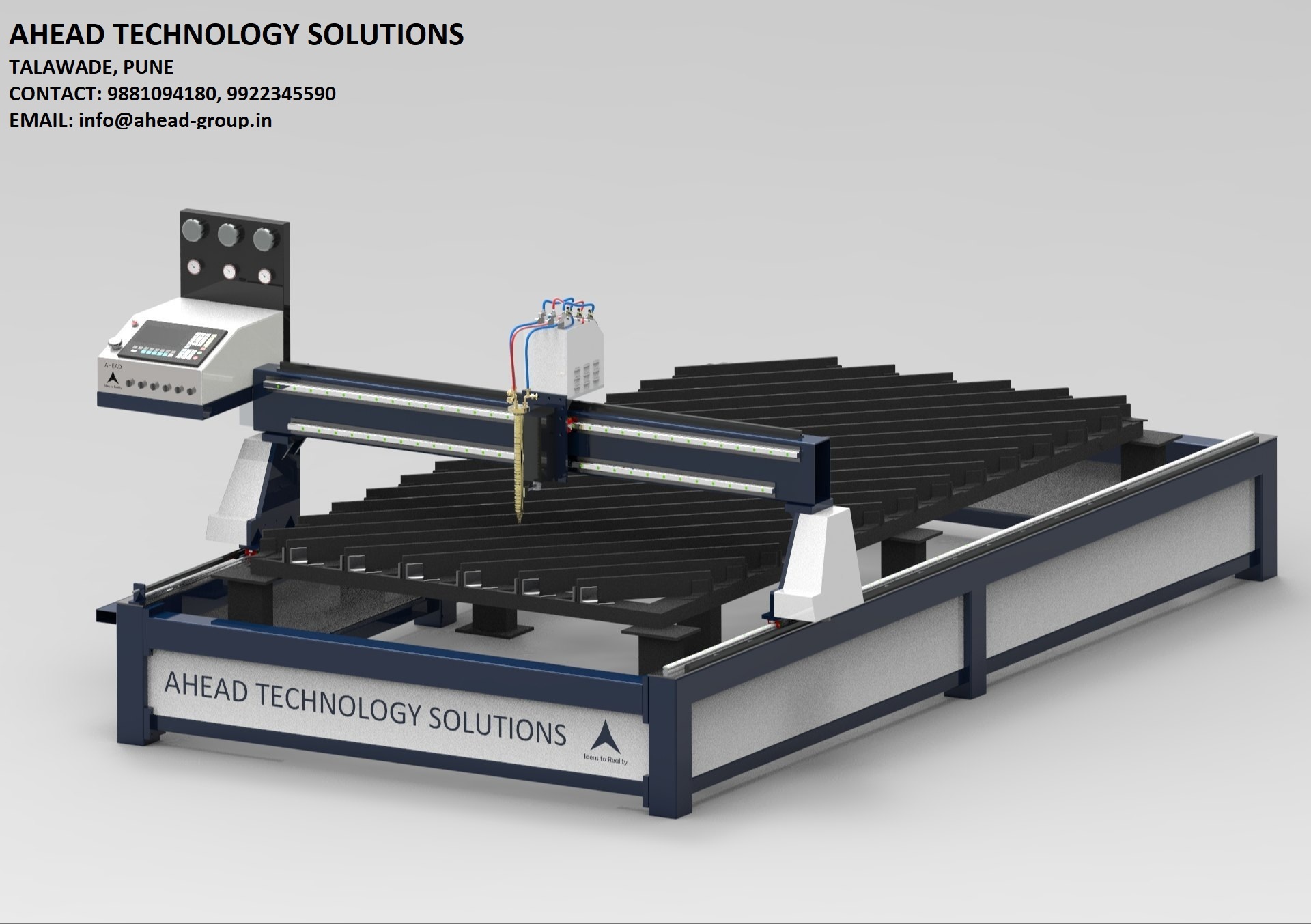

CNC Gas Cutting Machine

CNC Gas Cutting Machine Specification

- Type

- Against Manufacturing Defect

- Material

- Steel

- Capacity

- 5000 Kg/day

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cutting Speed

- 6000 mm/m

- Cutting Thickness

- 150 Millimeter (mm)

- Cutting Function

- Full Automatic

- Cooling System

- Air Cooling

- Drive Type

- Electric

- Weight (kg)

- 800 Kilograms (kg)

- Dimension (L*W*H)

- 14000 x 4000 x 1800 Millimeter (mm)

- Color

- Yellow

- Warranty

- 12 Months

CNC Gas Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva

- Payment Terms

- Paypal

- Supply Ability

- 120 Units Per Year

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, South America, Middle East, Africa

- Main Domestic Market

- Central India

About CNC Gas Cutting Machine

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Cutting Machine Category

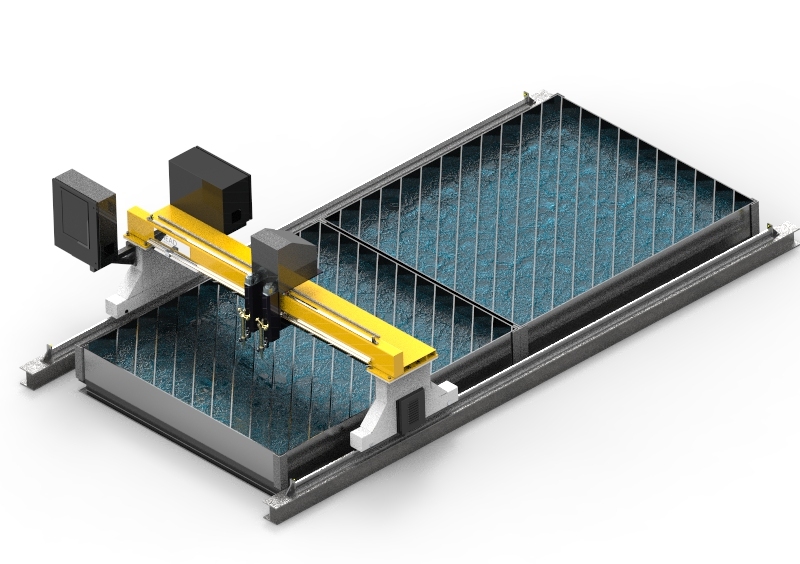

MS CNC Plasma Cutting Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : Stainless Steel

Cutting Function : Semi Automatic

Computerized : No

Portable CNC Profile Cutting Machine

Price 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : Stainless Steel

Cutting Function : Semi Automatic

Computerized : No

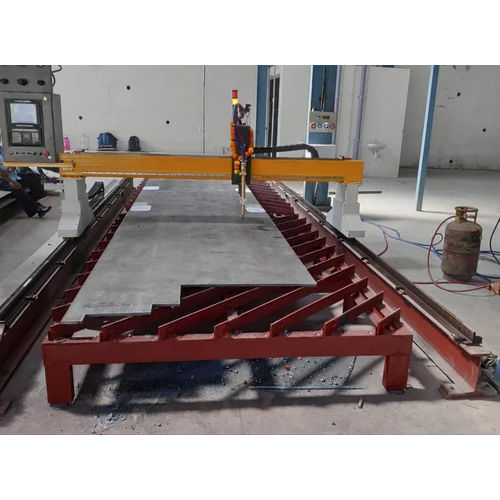

Single Phase CNC Gantry Profile Cutting Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : Stainless Steel

Cutting Function : Semi Automatic

Computerized : No

Oxy Fuel CNC Cutting Machine

Price 1250000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : Stainless Steel

Cutting Function : Semi Automatic

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS